How to Extend the Lifespan of a Waveguide Switch?

Waveguide switches are essential components in high-frequency systems such as radar, satellite communications, electronic warfare, and millimeter-wave test environments. Their reliability directly affects system performance and long-term stability. Because waveguide switches operate with extremely tight mechanical tolerances — especially in WR22, WR19, WR15, WR12, and WR10 millimeter-wave bands — ensuring a long service life requires proper selection, installation, and maintenance.

Based on industry best practices and the engineering expertise of AO Microwave, the following guidelines will help significantly extend the operational life of your waveguide switches.

1. Choose High-Precision and High-Quality Switches

The most effective way to guarantee long lifespan is to start with a robust, well-engineered product.

Waveguide switches designed for millimeter-wave applications must use:

-

precision-machined waveguide cavities

-

stable electromechanical actuators

-

high-quality bearings and alignment mechanisms

-

low-friction contact surfaces

Low-grade switches often experience premature wear, misalignment, and increased insertion loss.

AO Microwave manufactures waveguide switches from 5.85 GHz to 110 GHz using high-precision CNC machining, stable actuation mechanisms, and strict quality inspection, ensuring excellent durability and repeatability.

2. Avoid Excessive Actuation Cycles

Although waveguide switches are designed for repeated operation, every switch has a rated cycle life.

To extend lifetime:

-

avoid unnecessary switching

-

use software logic to minimize repeated toggling

-

adopt latching instead of failsafe switches when frequent switching is required

Latching switches maintain position without continuous power, reducing heat and mechanical stress.

3. Prevent Over-Torque on Waveguide Flanges

Improper mechanical installation is one of the most common causes of early switch failure.

Do not over-tighten screws, especially in mmWave models such as WR15/WR12/WR10.

Excessive torque can:

-

deform the flange

-

cause misalignment between the waveguide paths

-

increase insertion loss

-

damage internal moving mechanisms

Using torque-controlled tools and uniform tightening sequence is recommended.

4. Maintain a Clean, Dry, and Stable Operating Environment

Waveguide switches are sensitive to contamination and environmental conditions.

To extend life:

-

keep the interface clean and dust-free

-

avoid moisture and condensation

-

stabilize the operating temperature

-

prevent corrosion by storing the switch in dry conditions

Even small particles inside a WR10 waveguide can cause performance degradation.

5. Use Proper Power Levels

Every waveguide switch has maximum ratings for:

-

peak power

-

average power

-

RF leakage

-

switching speed

Operating beyond these limits can lead to overheating, mechanical stress, or arc damage. Always choose a switch with power handling margin above your application’s requirements.

6. Ensure Correct Voltage and Drive Conditions

Electromechanical switches rely on stable electrical drive signals.

To maintain lifetime:

-

avoid voltage spikes

-

prevent reverse polarity

-

use the recommended coil voltage

-

avoid rapid cycling that exceeds actuation speed specifications

Stable control voltage reduces internal wear and protects tiny mechanical components.

7. Regular Inspection and Preventive Maintenance

In systems requiring long-term continuous operation:

-

perform periodic inspection

-

check for flange wear

-

monitor insertion loss changes

-

confirm switching repeatability

-

verify actuator response time

Early detection of abnormalities protects the switch and the entire system.

Conclusion

Extending the lifespan of a waveguide switch requires a combination of proper product selection, correct installation, stable operating conditions, and routine maintenance. High-precision engineering plays a decisive role — and this is where AO Microwave delivers exceptional value.

With advanced machining technology, stringent quality control, and comprehensive waveguide switch solutions from 5.85 GHz to 110 GHz, AO Microwave ensures long-life, high-performance switches suitable for demanding aerospace, defense, telecom, and millimeter-wave testing environments.

Why Are Coaxial Suspension Line Filters the Right Choice for High-Performance RF Systems?

Why Are Coaxial Suspension Line Filters the Right Choice for High-Performance RF Systems?

What's the Coaxial Suspension Line Filter?

What's the Coaxial Suspension Line Filter?

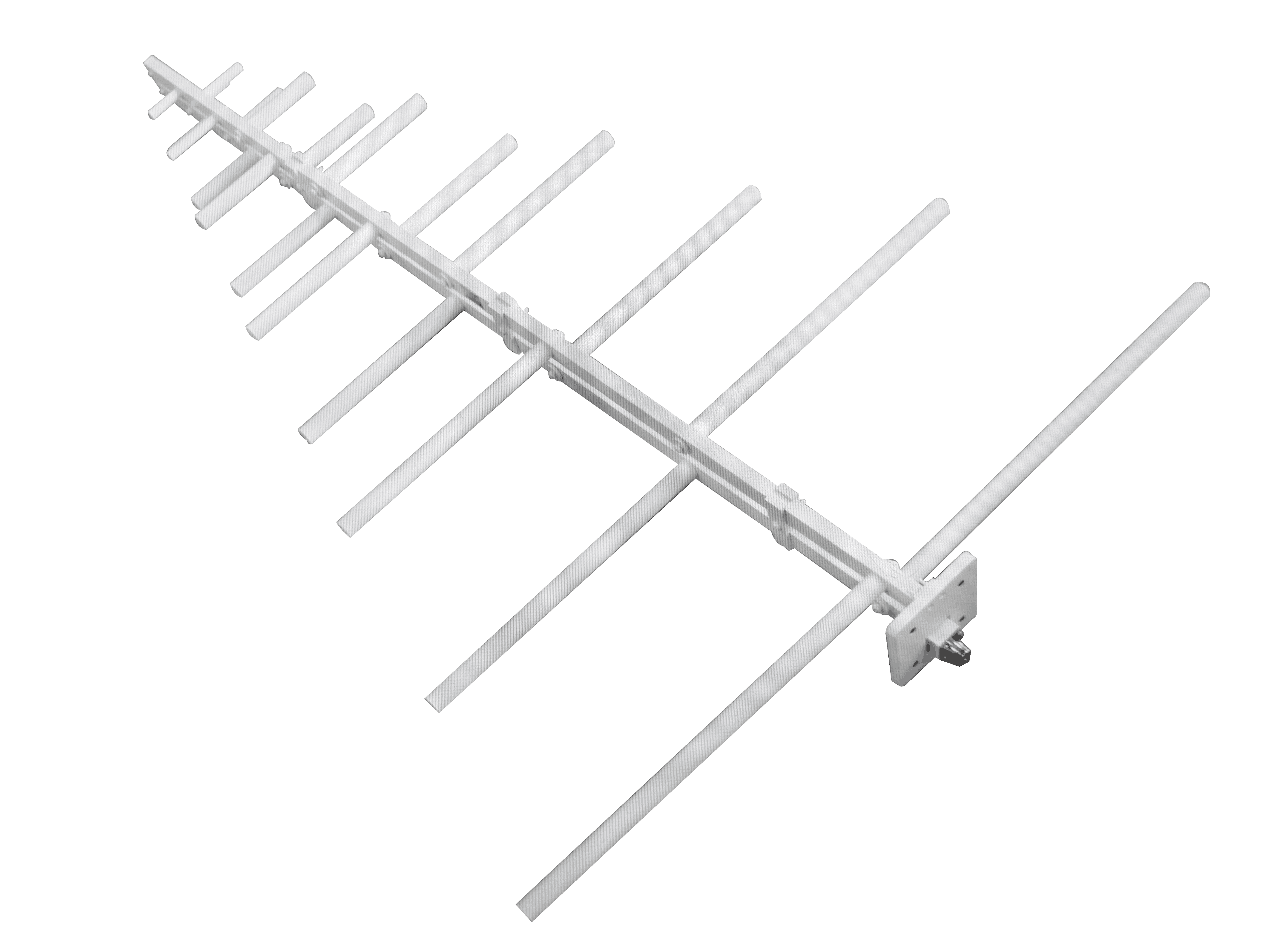

How to Choose a Log-Periodic Antenna for Long-Range Communication?

How to Choose a Log-Periodic Antenna for Long-Range Communication?

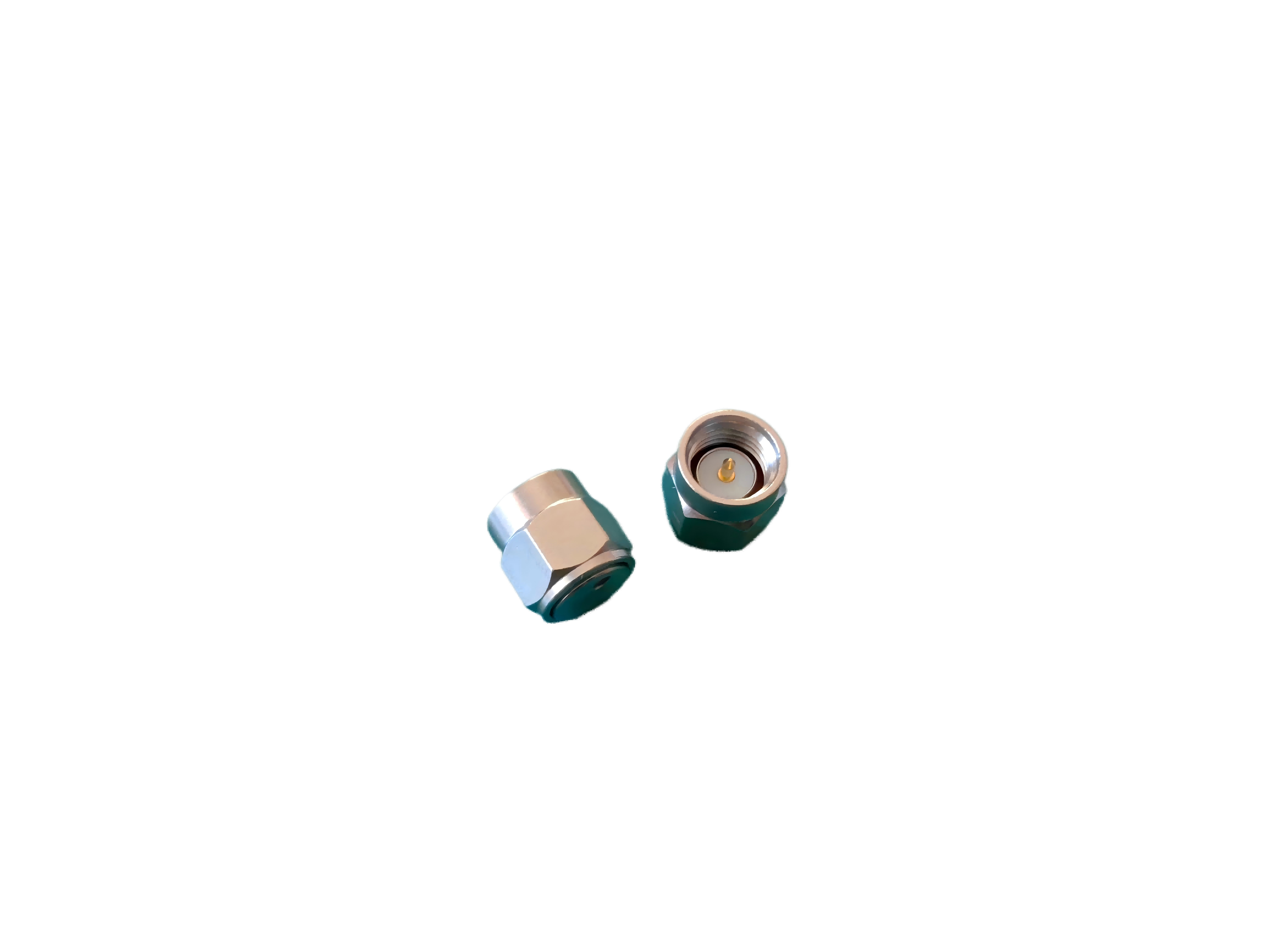

Compact Coaxial Loads: Why Short-Length Design Matters More Than You Think

Compact Coaxial Loads: Why Short-Length Design Matters More Than You Think